Why do artisan chocolate makers trust custom tins for freshness?

Freshness preservation is critical for chocolate: even the slightest exposure to moisture, light, or air can alter the delicate balance between cocoa solids, dairy flavors, and spice ingredients. That’s why many chocolate manufacturers work with specialized custom tin suppliers to source custom tins. To maintain the integrity of their products from production to retail display. From customized barrier properties and seals to beautiful branding and sustainable materials, custom tin manufacturers offer comprehensive solutions for freshness, convenience, and the look of premium tins.

Barrier properties of custom tins lock in aroma and texture.

At the heart of freshness preservation lies the superior barrier properties of custom tins. Unlike paper or plastic packaging, metal cans provide an impermeable barrier to oxygen, moisture, and light – three factors that degrade chocolate. Food-grade tinplate or aluminum cans are usually 0.23 to 0.30 mm thick and can completely block water vapor and ultraviolet rays. For handmade chocolate, this means preventing the appearance of white frost on the surface, while also locking in volatile aroma compounds, giving each bite of chocolate a unique aroma.

Many manufacturers add food-safe custom can liner, such as an epoxy phenolic or polyester coating, to enhance the barrier further and prevent the spread of metallic taste. These coatings comply with FDA and EU regulations, creating a chemically inert layer that protects the container and its contents.

Precision Sealing for Extended Shelf Life

In addition to barrier strength, the integrity of the seal on a custom chocolate tin is critical. High-quality tin lids feature a tight-fitting silicone gasket or beaded seal to create an airtight seal that prevents oxidation and contamination. In addition, automatic double-lock seams ensure uniform curling around the jar edges, eliminating weak spots that could allow air to enter. This meticulous sealing process, validated by vacuum decay and dye penetration testing, ensures that every batch of custom chocolate tins is made to specification. And, for chocolate manufacturers, it means a longer, predictable shelf life (typically three to six months) without having to rely on preservatives.

Material Selection and Coatings for Taste and Safety in custom tins

Selecting the right metal and coating system is a collaborative process between custom tin manufacturers and artisan chocolate makers. Tinplate offers strength and formability, while aluminum is lighter and more corrosion-resistant. Both substrates are available in various finishes: matte lacquer for a handcrafted feel, high-gloss powders for vibrant colors, and brushed metal for an upscale aesthetic.

The inner coating has strong chemical resistance to cocoa butter and dairy products, preventing migration that could affect flavor or safety. In addition, for single-origin dark chocolate, a neutral polyester liner is sufficient, retaining the delicate flavor of the cocoa beans without introducing any off-flavors.

Design flexibility for custom tin cans

Beyond airtightness, custom tin cans offer unique design features that optimize chocolate freshness through portioning and temperature management. Multi-compartment cans with removable liners allow chocolatiers to distinguish between dark, milk, and white flavors without cross-contamination. Unique shapes, such as hexagonal boxes or slim rectangular tins, facilitate portion control and protect individual chocolates from unwanted light or exposure.

See also Wedding Planning Tips for a Stress-Free Celebration

In addition, the thermal mass of metal provides a degree of insulation, buffering chocolate from blooming or changes in texture caused by rapid temperature fluctuations—dark chocolate benefits from this thermal stability, especially during transport and in-store display. With a well-designed can, manufacturers can offer custom-made cans for chocolate.

Branding and consumer experience

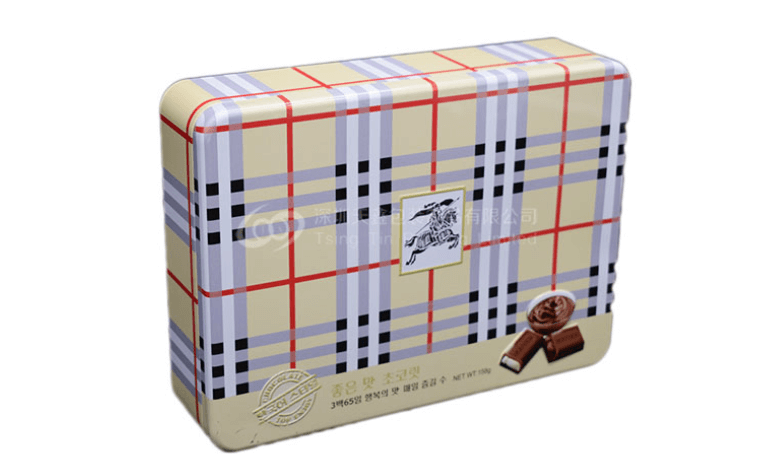

Packaging is a key component of the consumer experience in the premium chocolate market. Custom tins give the chocolatier a tangible sense of craftsmanship and luxury, reinforcing the chocolate maker’s brand story. Techniques such as offset printing, embossing, debossing, and hot stamping enhance the unboxing experience by providing beautiful patterns, gold decorations, and touches.

Chocolatiers often embed small windows or transparent PU films on custom chocolate tins to showcase truffles or engraved chocolates, allowing customers to glimpse the treasures inside. The reusable nature of metal cans encourages customers to reuse them, such as storing tea, spices, or souvenirs, and allows the brand to live in the home long after the customer has enjoyed the last bite.

Ultimately

Custom tins provide an all-in-one tin packaging solution with superior barrier properties, airtightness, custom materials, temperature management, brand diversity, sustainability certifications, and strict quality standards. Working with professional custom tin manufacturers from small-batch truffle producers to world-renowned chocolate manufacturers ensures that every handmade chocolate is delivered to consumers in the best condition, thereby improving consumer satisfaction and consolidating brand reputation.